Yokogawa Gas Calorimeter - CM6G

2016-05-27 17:17:35

Description:

The CM6G Gas Calorimeter is used to measure and control the calorific value or Wobbe Index (WI) of the sample gas. In this calorimeter, the sample gas is burnt at the burner with air and the temperature difference between the combustion exhaust gas and the feed air at the burner inlet is detected by using a thermocouple. This calorimeter detects the flow rate of both the sample gas and the air as the differential pressure by using the orifice and converts the differential pressure to the digital signal then compensates the flow rate variation by the digital calculation. This method gives an excellent high reliability, therefore it can be used for the control of thermal input for the various type furnaces in the steel mill and petrochemical industries, also for the calorie control of the town gas. * This product is not available in Europe.……

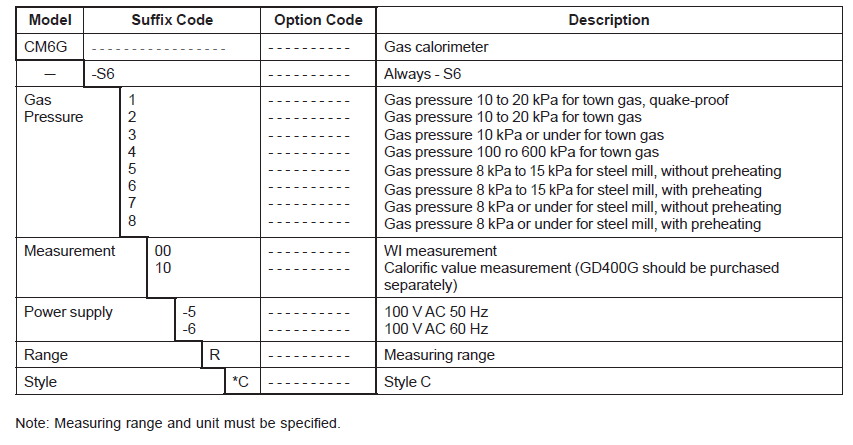

CM6G-S6100-5R*C,CM6G-S6200-5R*C,CM6G-S6300-5R*C,CM6G-S6400-5R*C,CM6G-S6500-5R*C,CM6G-S6600-5R*C,CM6G-S6700-5R*C,CM6G-S6800-5R*C

CM6G-S6110-5R*C,CM6G-S6210-5R*C,CM6G-S6310-5R*C,CM6G-S6410-5R*C,CM6G-S6510-5R*C,CM6G-S6610-5R*C,CM6G-S6710-5R*C,CM6G-S6810-5R*C

CM6G-S6100-6R*C,CM6G-S6200-6R*C,CM6G-S6300-6R*C,CM6G-S6400-6R*C,CM6G-S6500-6R*C,CM6G-S6600-6R*C,CM6G-S6700-6R*C,CM6G-S6800-6R*C

CM6G-S6110-6R*C,CM6G-S6210-6R*C,CM6G-S6310-6R*C,CM6G-S6410-6R*C,CM6G-S6510-6R*C,CM6G-S6610-6R*C,CM6G-S6710-6R*C,CM6G-S6810-6R*C

New Products

G.M. International X1-IS-AO-02-S I.S. SIL2 HART® Isolating Driver module

G.M. International X1-IS-AO-02-S I.S. SIL2 HART® Isolating Driver module. GMI Intrinsically Safe Isolators, Analog Output

G.M. International D1020S SIL 2 Powered Isolating Driver

G.M. International D1020S SIL 2 Powered Isolating Driver Smart-HART® compatible DIN-Rail. GMI Intrinsically Safe Isolators

G.M. International D1020D SIL 2 Powered Isolating Driver

G.M. International D1020D SIL 2 Powered Isolating Driver Smart-HART® compatible DIN-Rail. GMI Intrinsically Safe Isolators

G.M. International X1-IS-AO-01-S I.S. SIL3 HART® Isolating Driver module

G.M. International X1-IS-AO-01-S I.S. SIL3 HART® Isolating Driver module. GMI Intrinsically Safe Isolators, Analog Output

Assortments

▶ Pressure Transmitter EJA

▶ Pressure Transmitters EJA-E

▶ Pressue Transmitter EJX

▶ Safety Instrumented System (SIS)

▶ Valve Positioners & Converters

▶ Field Mount Indicators

▶ Temperature Transmitters

▶ Magnetic Flowmeters

▶ Vortex Flowmeter

▶ Ultrasonic Flowmeters

▶ Coriolis Mass Flowmeters - ROTAMASS 3-Series

▶ Variable Area Flowmeters – Rotameters

▶ Device Smart Communicators

▶ PORTABLE AND HANDHELD INSTRUMENTS

▶ Distributed Control System (DCS)

▶ Process Analyzers

▶ Paperless Recorders

▶ Strip Chart Recorders

▶ Data Acquisition Equipment

▶ UT Series Temperature Controllers

▶ UP Series Program Controllers

▶ UM Series Digital Indicators with Alarms

▶ UT100 Series Temperature Controllers

▶ UD Series Manual Setters

▶ Limit Controllers

▶ YS Series Single-loop Controllers

Description

CM6G

The CM6G Gas Calorimeter is used to measure and control the calorific value or Wobbe Index (WI) of the sample gas. In this calorimeter, the sample gas is burnt at the burner with air and the temperature difference between the combustion exhaust gas and the feed air at the burner inlet is detected by using a thermocouple.

This calorimeter detects the flow rate of both the sample gas and the air as the differential pressure by using the orifice and converts the differential pressure to the digital signal then compensates the flow rate variation by the digital calculation. This method gives an excellent high reliability, therefore it can be used for the control of thermal input for the various type furnaces in the steel mill and petrochemical industries, also for the calorie control of the town gas.

* This product is not available in Europe.

The construction of the detector is solid and durable, and easy for maintenance and operation.

Special patent construction is adopted at the mixing point of the heat exhaust gas and the heat absorbing air from the detector, and it improves the response time.

Excellent high reliability by using orifices to detect differential pressure both air and gas and to calculate after compensating the indication errors caused by the flow rate variations.

| Town Gas Application | |

| Measurement object | Measurement and control of WI or the calorific value of fuel gas for town gas. |

| Measuring Range | 3 to 62 MJ/Nm3 |

| Sample gas condition | Dust: 5 mg/Nm3 or less< Temperature: 50℃ or less Humidity: dew point of 0℃ or less Pressure: (1) 10 to 20 kPa: standard, (2) 10 kPa or under: with pump, (3) 100 to 600 kPa: with pressure reducing valve |

| Range | Select scale range (Span): General Gas: 30 to 50% of maximum value of the span. Butane or Butene + Air:20 to 30% of maximum value of the span. Propane or Propylene + Air: 25 to 40% of maximum value of the span. |

| Output signal | 1 to 5 V DC, 4 to 20 mA DC (simultaneously), non-isolated, load resistance 750Ω or less |

| Alarm Contact Output | Flame off alarm; 100 V AC, 5 A, closed when alarm occurs Temperature alarm; 100 V AC, 3 A, closed when alarm occurs |

| Contact Input | Remote ignition (custom order); 24 V DC, 0.1 A or more |

| Sample Gas Flow Rate | Approx. 10 l/min |

| Utility | Instrument Air: Approx. 50 Nl/min, pressure 300 to 700 kPa, dew point of 0℃ or less Power Supply: 100 V AC ±10%, single phase, 50/60 Hz, 860 VA max. |

| Panel | Construction: For indoor installation, rack panel. |

| Ambient Temperature | 0 to 40℃ and no rapid change in ambient temperature is allowed. |

| Repeatability | When the calorific value means 6.3 MJ/Nm3 or higher, Calorific : ±1.0% of measured value WI : ±0.5% of measured value |

| Steel Mill Application | |

| Measurement object | Measurement and control of WI or the calorific value of fuel gas for a steel mill. |

| Measuring Range | 3 to 62 MJ/Nm3 |

| Sample gas condition | Dust: 100 mg/Nm3 or less Temperature: 50℃ or less Humidity: dew point of 0℃ or less Pressure: (1) 8 to 15 kPa: standard, (2) 8 kPa or under: with pump |

| Range | Select scale range (Span): General Gas: 30 to 50% of maximum value of the span. Butane or Butene + Air:20 to 30% of maximum value of the span. Propane or Propylene + Air: 25 to 40% of maximum value of the span. |

| Output | 1 to 5 V DC, 4 to 20 mA DC (simultaneously), non-isolated, load resistance 750Ω or less |

| Alarm Contact Output | Flame off alarm; 100 V AC, 5 A, closed when alarm occurs Temperature alarm; 100 V AC, 3 A, closed when alarm occurs |

| Contact Input | Remote ignition (custom order); 24 V DC, 0.1 A or more |

| Sample Gas Flow Rate | Approx. 10 l/min |

| Utility | Water: Approx. 0.2 l/min, pressure 200 to 600 kPa Instrument Air: Approx. 50 Nl/min, pressure 300 to 700 kPa, dew point of 0℃ or less Power Supply: 100 V AC ±10%, single phase, 50/60 Hz, 1100 VA max. |

| Panel | Construction: For indoor installation, rack panel. |

| Ambient Temperature | 0 to 40℃ and no rapid change in ambient temperature is allowed. |

| Repeatability | When the calorific value means 6.3 MJ/Nm3 or higher, Calorific : ±1.0% of measured value WI : ±0.5% of measured value |

Gas Calorimeter Models:

CM6G-S6100-5R*C,CM6G-S6200-5R*C,CM6G-S6300-5R*C,CM6G-S6400-5R*C,CM6G-S6500-5R*C,CM6G-S6600-5R*C,CM6G-S6700-5R*C,CM6G-S6800-5R*C

CM6G-S6110-5R*C,CM6G-S6210-5R*C,CM6G-S6310-5R*C,CM6G-S6410-5R*C,CM6G-S6510-5R*C,CM6G-S6610-5R*C,CM6G-S6710-5R*C,CM6G-S6810-5R*C

CM6G-S6100-6R*C,CM6G-S6200-6R*C,CM6G-S6300-6R*C,CM6G-S6400-6R*C,CM6G-S6500-6R*C,CM6G-S6600-6R*C,CM6G-S6700-6R*C,CM6G-S6800-6R*C

CM6G-S6110-6R*C,CM6G-S6210-6R*C,CM6G-S6310-6R*C,CM6G-S6410-6R*C,CM6G-S6510-6R*C,CM6G-S6610-6R*C,CM6G-S6710-6R*C,CM6G-S6810-6R*C