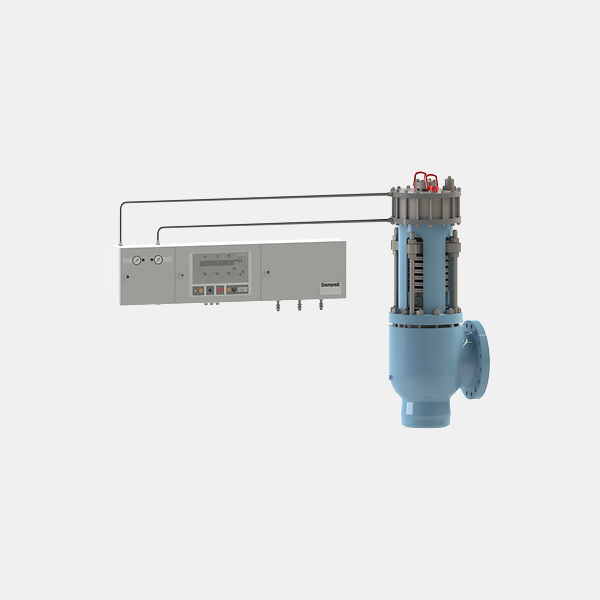

Sempell Model SOT High pressure steam safety valve

2025-09-25 14:16:29

Description:

The Sempell Model SOT is a high-pressure steam safety valve designed for boiler protection and steam system safety.……

New Products

G.M. International X1-IS-AO-02-S I.S. SIL2 HART® Isolating Driver module

G.M. International X1-IS-AO-02-S I.S. SIL2 HART® Isolating Driver module. GMI Intrinsically Safe Isolators, Analog Output

G.M. International D1020S SIL 2 Powered Isolating Driver

G.M. International D1020S SIL 2 Powered Isolating Driver Smart-HART® compatible DIN-Rail. GMI Intrinsically Safe Isolators

G.M. International D1020D SIL 2 Powered Isolating Driver

G.M. International D1020D SIL 2 Powered Isolating Driver Smart-HART® compatible DIN-Rail. GMI Intrinsically Safe Isolators

G.M. International X1-IS-AO-01-S I.S. SIL3 HART® Isolating Driver module

G.M. International X1-IS-AO-01-S I.S. SIL3 HART® Isolating Driver module. GMI Intrinsically Safe Isolators, Analog Output

Assortments

Description

The Sempell Model SOT is a high-pressure steam safety valve designed for boiler protection and steam system safety. It is of the disc-spring type and can be ordered with welding ends or flanged connections. The valve is engineered to relieve excess pressure safely before damage can occur, especially in high-temperature and high-pressure steam services.

Key Features

Disc Spring Design — Uses disc springs rather than typical helical springs, enabling higher forces for a given size. This gives better performance in high set pressures and heavy service.

Open Bonnet / Balanced Piston Construction — Ensures stable operation under varying pressure conditions.

High Tightness up to Set Pressure — Due to supplementary load; helps prevent leakage until pressure reaches the set-point.

Smooth Operation with No “Popping” Forces — The lift and actuation occur in a controlled manner, reducing pressure spikes.

Mechanical Lift Stop — Ensures functional stability over repeated cycles, preventing over-stroke.

Locking Feature for Hydrostatic Testing — Can be locked for hydrostatic test without additional parts.

High Allowable Back Pressure — The design tolerates high system back pressure without compromising safety or operation.

Advantages

High Performance in Severe Conditions — Designed for systems with very high pressures and temperatures; ideal for steam, superheated steam, etc.

Reliable Operation & Tight Sealing — Good leakage tightness up to set pressure until activation, controlled lift, and robust mechanical stops.

Durability & Material Versatility — Wide selection of materials allows matching to the specific steam chemistry, temperature, and environment.

Lower Maintenance and Testing Ease — Features like lock-for-hydrostatic testing without extra parts, mechanical lift stops help in maintenance and reliable re-commissioning.

Customizable — Various sizes, orifice diameters, body materials, connection types (flanged, welded), ability to include position indication etc.

Recommended Uses / Applications

Boiler overpressure protection in power plants or steam generation systems.

Systems needing high set pressure safety valves with minimal leakage and reliable operation at high temperature.

Steam systems with strict requirements for tight sealing and durability under severe service.

By partnering with HKXYTECH, customers gain access to reliable Sempell Model SOT technology and a trusted supplier focused on minimizing downtime, improving safety, and ensuring long-term performance.